Integrated Fabrication Process

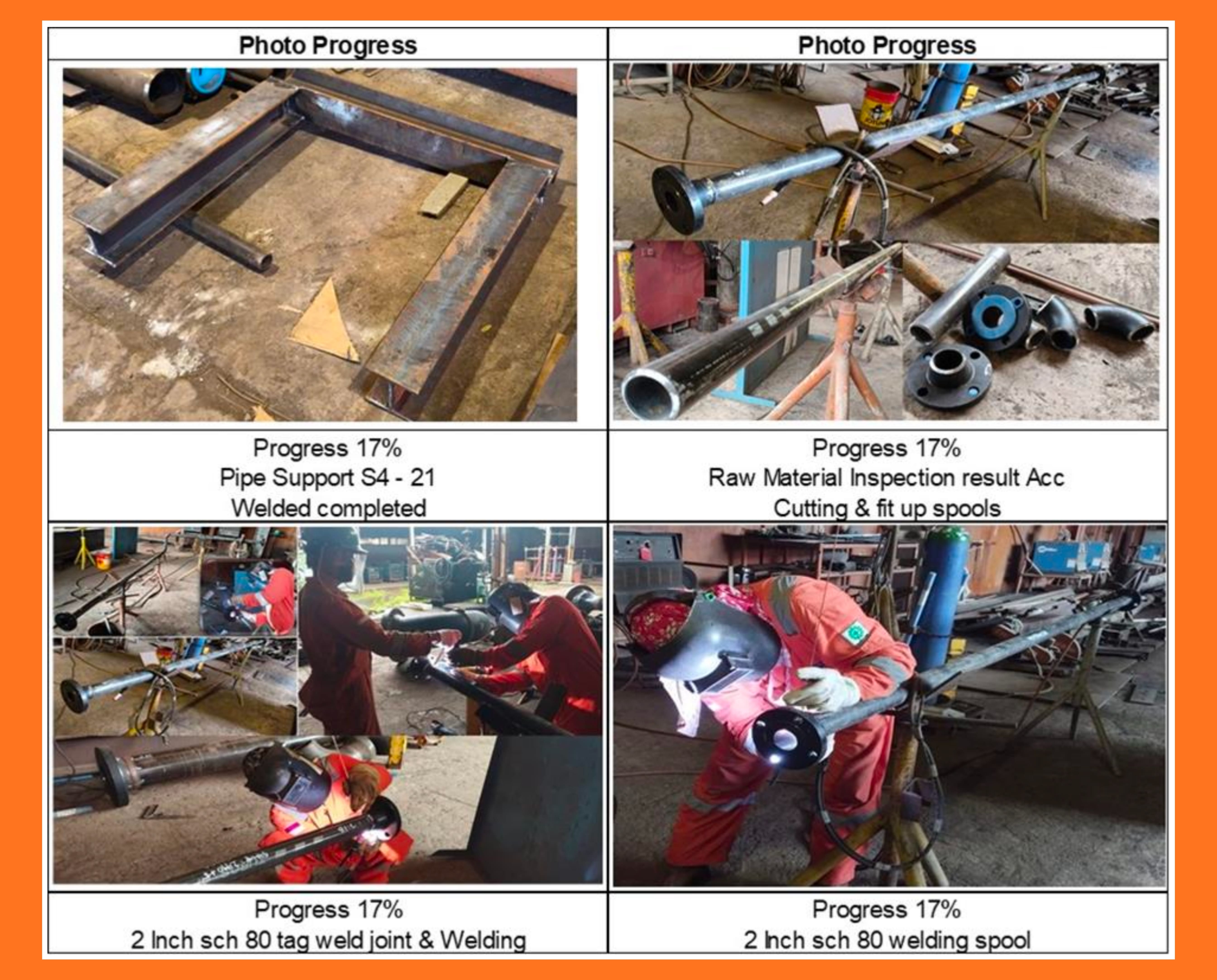

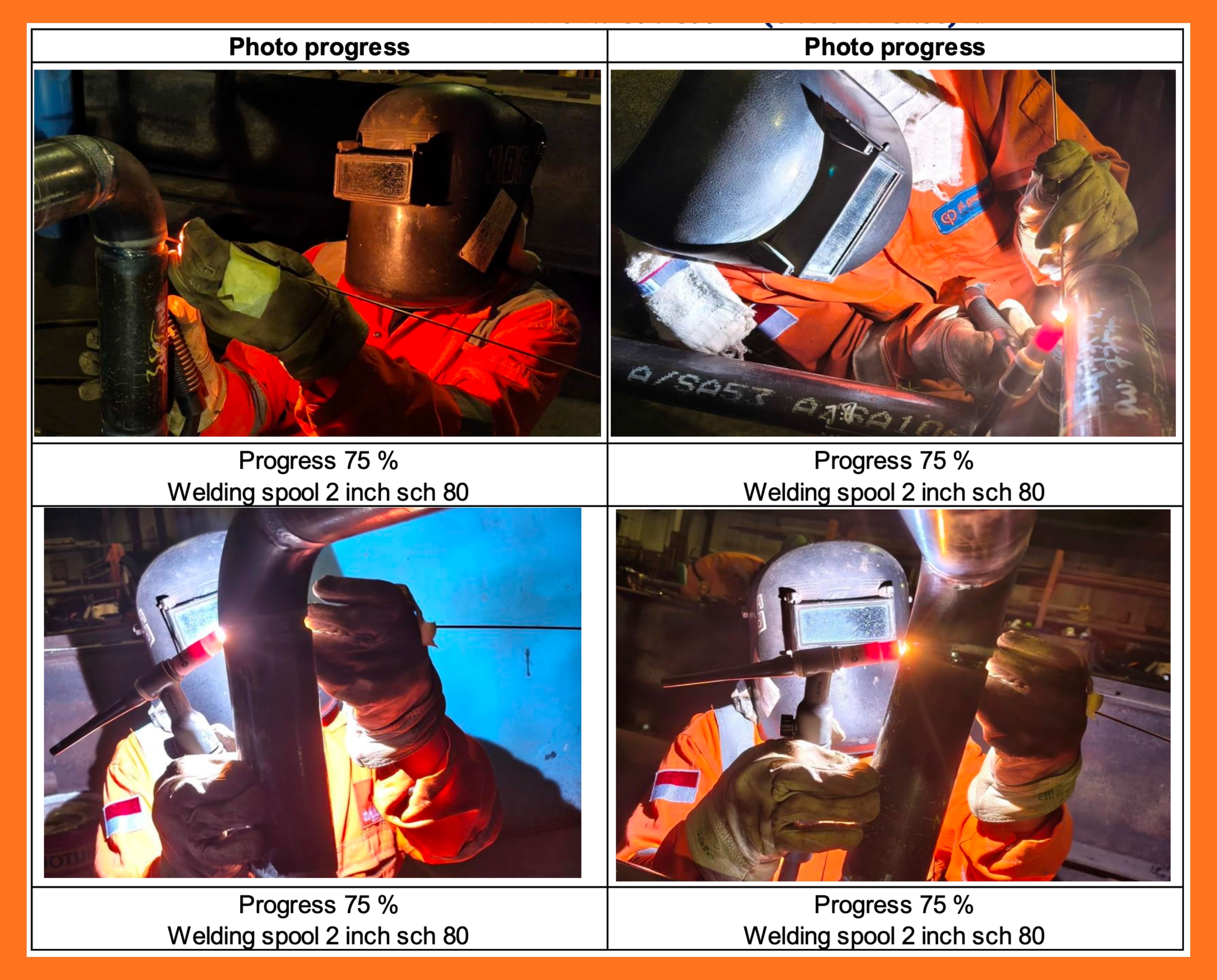

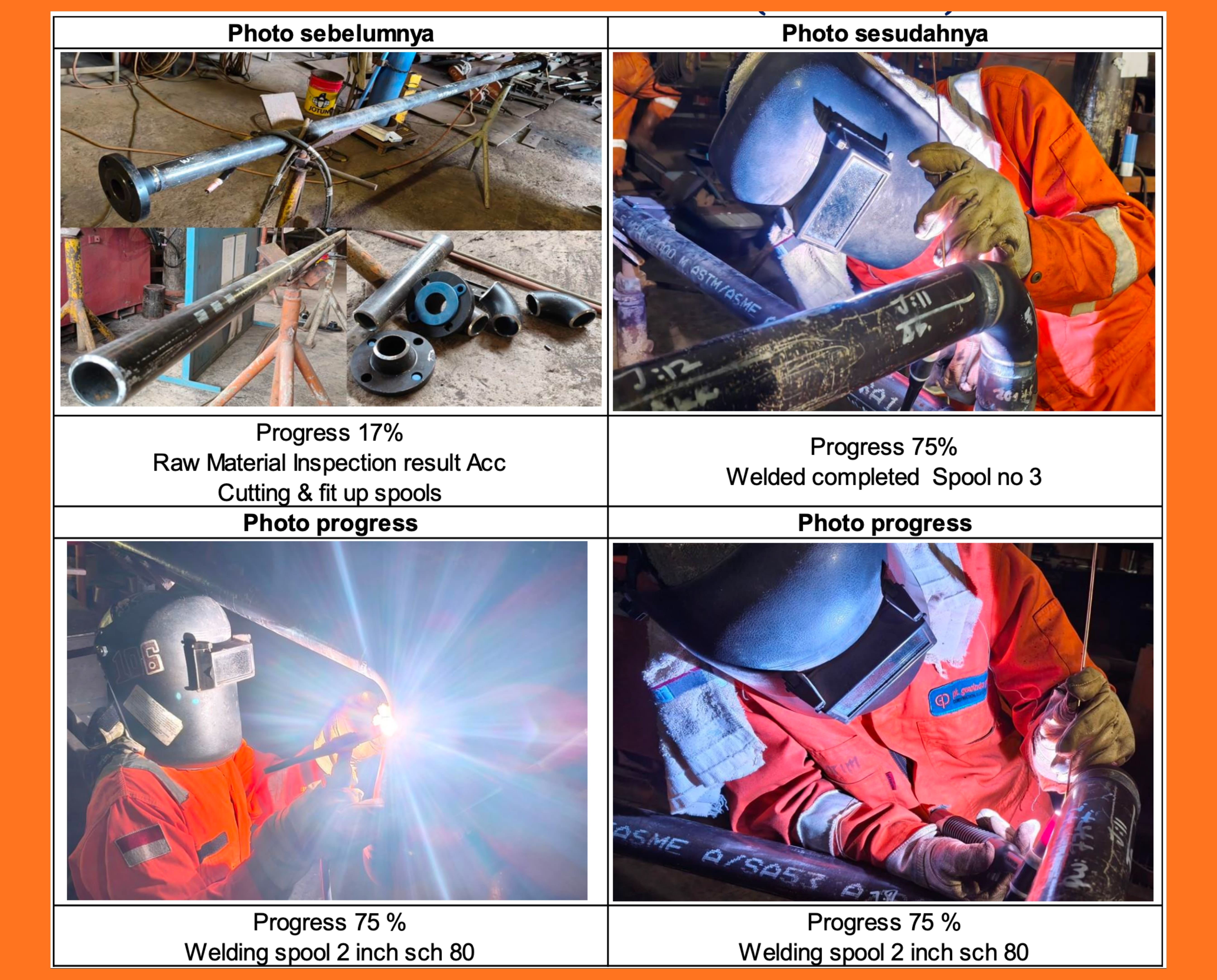

The workflow commenced with a rigorous Raw Material Inspection and precision cutting. Our expert technical team worked synergistically to perform the fit-up and welding of the 2-inch Sch 80 welding spools. The total workload included 26 D-inch Sch 80 components and one pipe support riser unit. Every weld joint was ensured to meet premium quality through strict technical evaluations.

In line with our commitment to satisfactory results, all fabrications underwent comprehensive Non-Destructive Testing (NDT), including Magnetic Particle Inspection (MPI) and Radiography Testing (RT). All test results were declared Acceptable, ensuring the structural integrity of the spools for optimal operational conditions.

Final Quality and On-Time Delivery

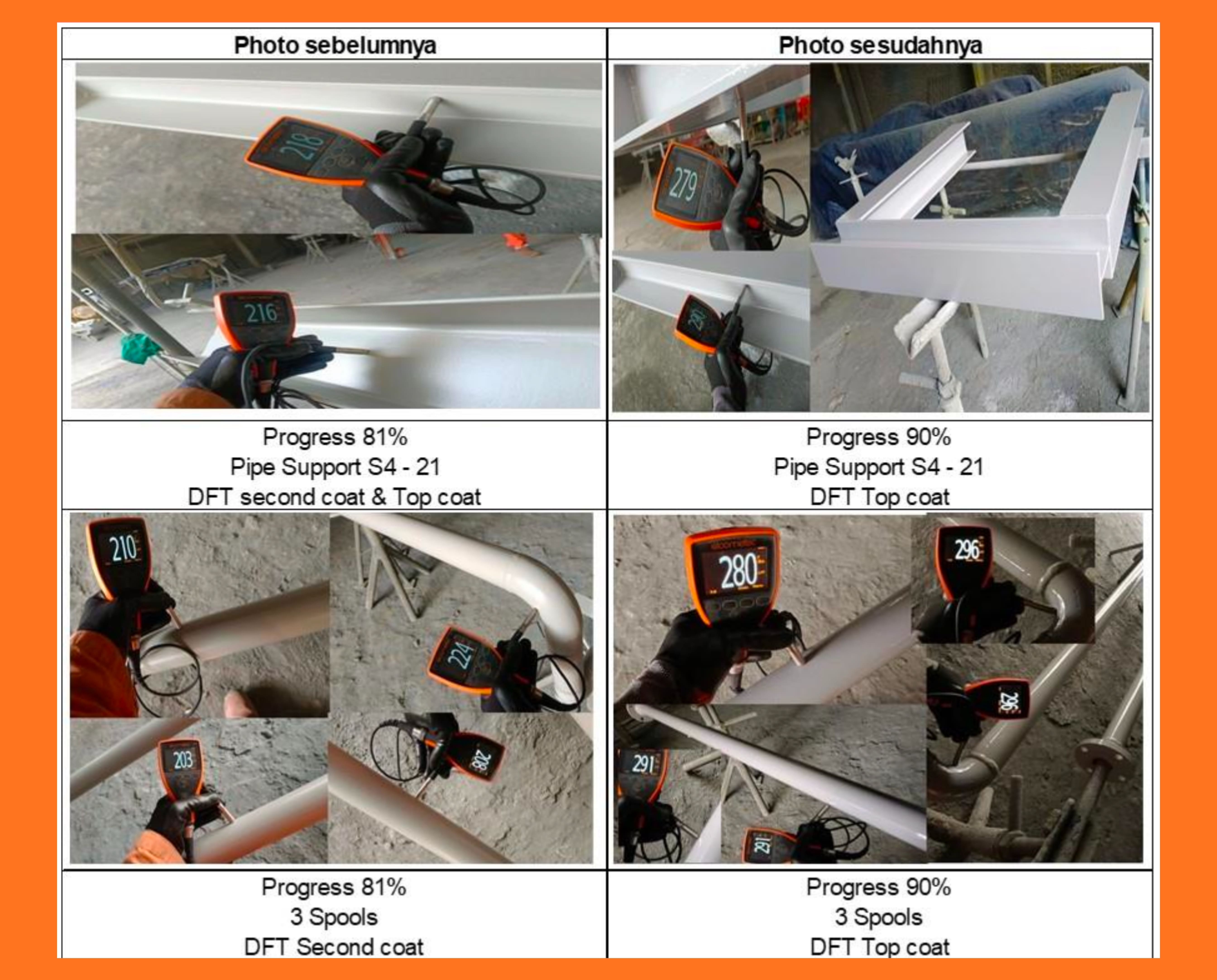

Following the successful fabrication and hydrotesting phases, the components moved to the corrosion protection stage. This process included blasting and the application of a multi-layer coating system: primer, second coat, and a final top coat in Grey RAL 7004, per technical specifications. Dry Film Thickness (DFT) measurements were conducted at every stage to guarantee material durability in extreme environments.

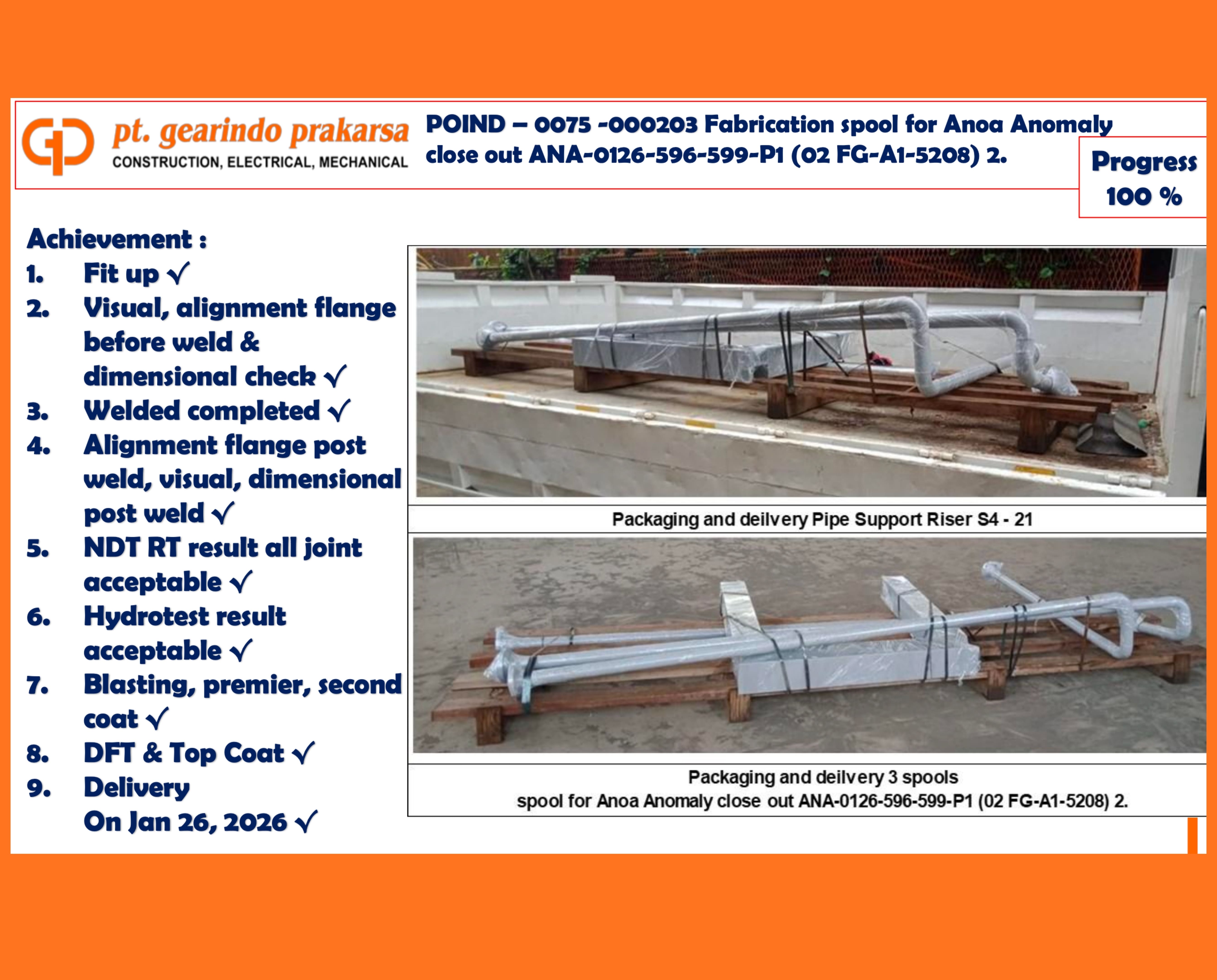

On January 26th, 2026, the complete shipment—consisting of 3 spools and the pipe support—was packaged and dispatched to its destination. Achieving 100% progress within this timeframe proves that PT Gearindo Prakarsa prioritizes customer satisfaction through hard work and uncompromised technical standards. We continue to move forward, delivering high-quality work to drive the nation’s industrial progress.