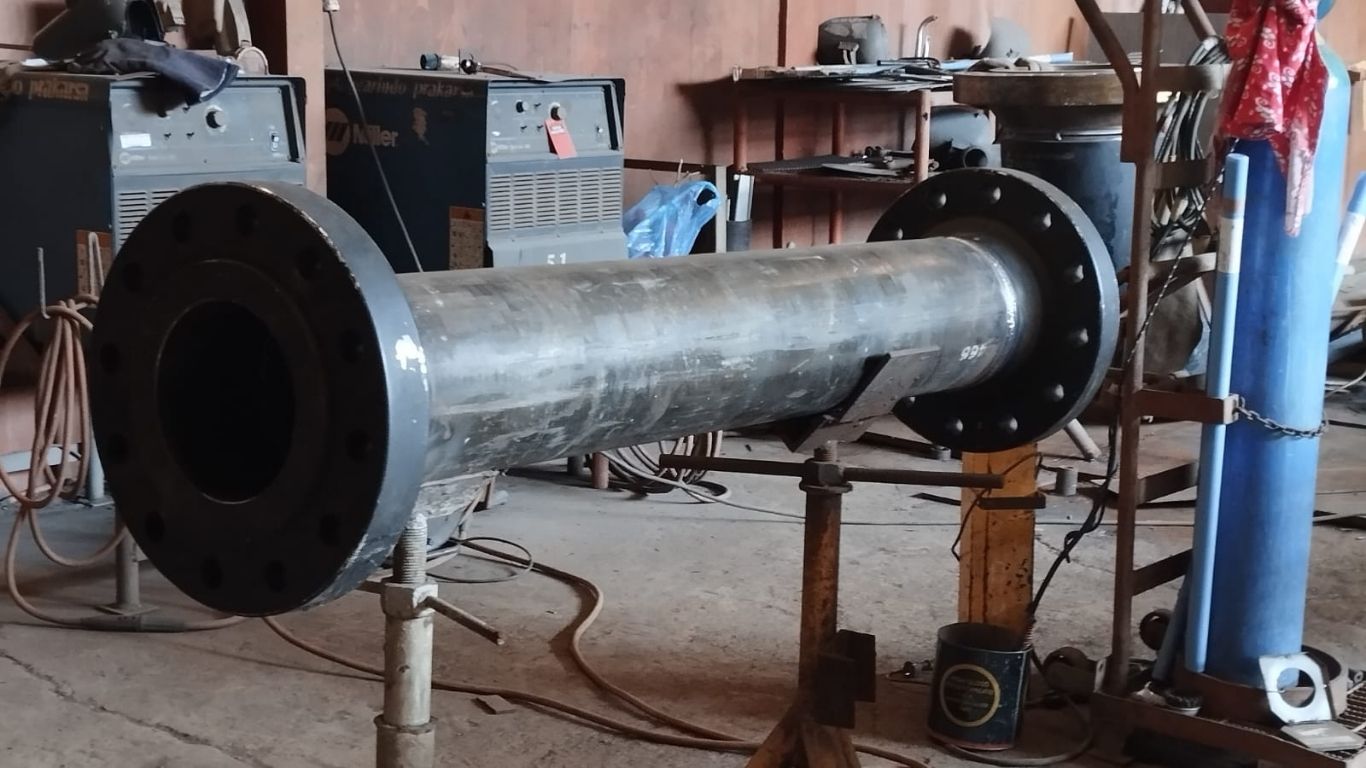

To guarantee the structural integrity of every component, the fabrication of these pipe supports is proceeding exactly according to the Inspection Test Plan (ITP) and the engineering requirement testing on the approved drawings. Each spool undergoes a battery of quality assurance steps, including:

- Non-Destructive Testing (NDT): Ensuring internal weld quality through precise examination.

- Hydro Testing: Verifying pressure containment and leak resistance under operational conditions.

- Blasting & Painting: Providing industrial-grade surface protection to ensure long-term durability.

On Track for Success

Efficiency and quality control are the cornerstones of our operations. Our streamlined workflow and the expertise of our onsite crew allow us to maintain a steady pace without compromising the exacting standards our clients expect. By adhering strictly to approved CAD specifications and safety protocols, we ensure that every piece of equipment leaving our workshop is built to last.

We remain highly optimistic and fully committed to our project milestones. With the current rate of progress, we are on track to complete the fabrication and all final treatments as scheduled. We look forward to the successful delivery to the client warehouse by February 4, 2026, reinforcing our reputation for reliability and timely project execution in the energy and industrial sectors.